Gamolon

Master Poster

- Joined

- Dec 6, 2006

- Messages

- 2,702

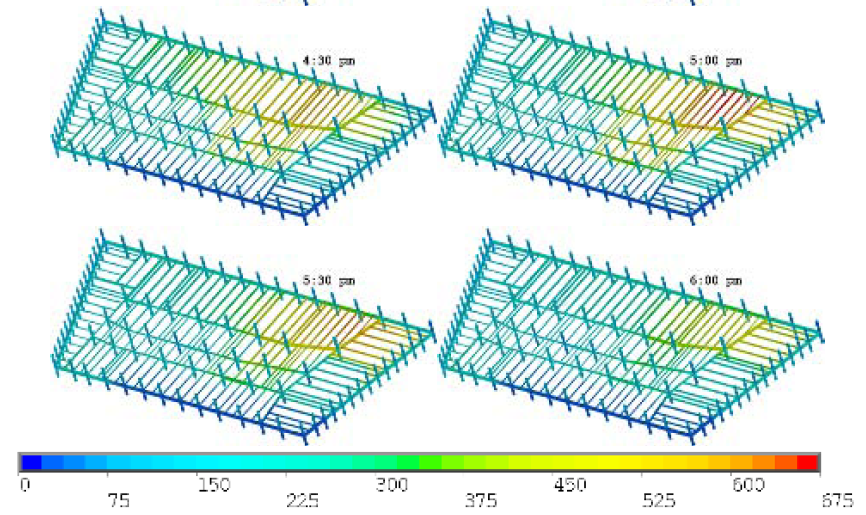

Do you believe Table 10-1 or the color correctness of the graphic?

That is your problem right there.

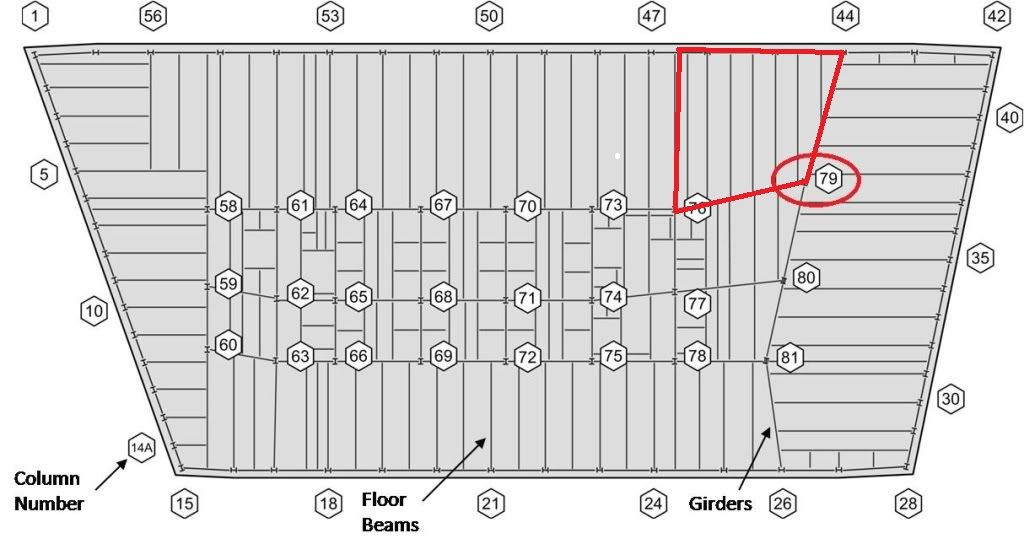

NIST does not define what E, NE, S is. You have to determine what NIST means in using those directional designations by looking at the colored beam temperature diagrams.

You're putting YOUR interpretations onto what THEY mean and it doesn't agree when used in conjunction with the diagrams.

To put it simply, it is unclear what areas are encompassed within NIST's directional designations until you look at the diagrams.