Newtons Bit

Penultimate Amazing

- Joined

- Apr 12, 2007

- Messages

- 10,049

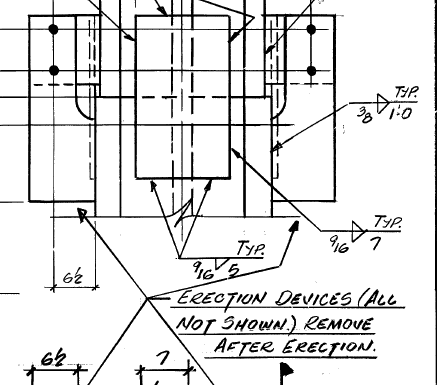

A couple of quick sketches for those who'd like to see how the column splices work.

This was in response to Tony's assurance that the splice joints would provide just as much stiffness & resistance to buckling (i.e., equivalent MoI) as would a continuous, unbroken beam. An assumption that was integral to his calculations about how much the column would deflect in response to side load, and to his calculation as to how many stories of column 79 would have to be unsupported before it went unstable.

Tony's assurances turn out to be false. Numbers below.

First sketches:

Note: all components drawn to scale.

Isometric view of splice joints & seats.

[qimg]http://www.internationalskeptics.com/forums/picture.php?albumid=553&pictureid=6214[/qimg]

[Note: bolts exploded for clarity]

Top view of splice joints & seats

[qimg]http://www.internationalskeptics.com/forums/picture.php?albumid=553&pictureid=6215[/qimg]

[Note: seat on south side of column not shown.]

Calculation of Moment of Inertia of built-up column versus bolts

MoI calculated for deflections in east-west direction, i.e., "about vertical axis of top view thru center of column"Component|I|A|d|n|Itot

||(in^2)|in||(in^4)

Column|4715|214.5|0|1|4715

Side plates|16.3|48.8|9.95|2|9679

Total|||||14394

|||||

Bolts|0.05|0.7854|17.45|8|1913

|||||

|Values verified|||Ratio (beam/bolt)|7.5

Observations

1. The splice plates are incredibly thin. The MOI calculation assumes that they will stay straight & untorqued when side load applied. This assumption seems wildly optimistic to me.

2. From the table: The MoI's of the various components are calculated using the standard "parallel axis theorem". From the table, one can see that the MoI of the column is about 7.5x greater than the MoI of the 8 bolts.

3. MoI of joint to deflections in north south direction (about horizontal axis in top view) is pretty darn close to zero. The splice plates are simply going to torque, and the alignment plates, not being welded to upper column, provides zero recoverable strain, and therefore do not contribute to MoI.

4. The bolts are thermally isolated from the heat sinking mass of the columns. They are going to heat up & lose strength in a fire far faster than the columns themselves.

That's not completely accurate. The column will still provide compression resistance through part of the shape when the splice is subjected to bending. The calculation of MoI needs to follow something similar to how it is calculated in reinforced concrete.

It's not a simple calculation, however.