Tony,

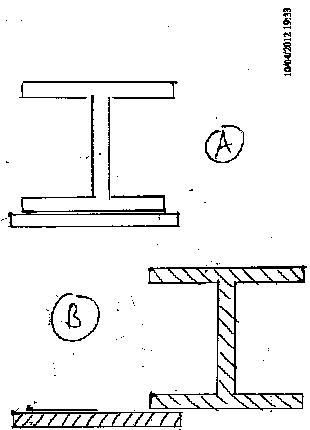

You'd make your prose a lot easier to follow if you were to supply a quick sketch, showing forces, moments, & identifying where you are trying to calculate stresses. You know, like people supply when they are trying to explain their stuff clearly.

___

And your explanations leave a lot to be desired.

For example, please explain how you got inches4 out of this calculation:

It doesn't help your credibility to leave out dimensions & inexplicably change inches3 into inches4.

Without a diagram, it's tough to tell what you are calculating here.

For calculating MOI of a weld it is treated as a line with no width and so the length or height of the weld is cubed as it is for a prismatic beam with (bh^3)/12 but no b term. The 6 is in the denominator here is due to there being two welds.

The units resulting from MY/I here should be lbs./inch not psi.

So a correction to the above would be the bending load is 3,578 lbs./inch. The shear load can also be calculated in lbs./inch by considering only the length of the weld, and it would be 81,984 lbs. / (2 x 18 in.) = 2,277 lbs./inch.

The resultant is sqrt[2,227^2 + 3,578^2] = 4,241 lbs./inch.

Stress = resultant/(0.707 x weld size) so 4,241 / (0.707 x 0.3125) = 19,195 psi. The factor of safety would be 34,000/19,195 = 1.77. This is for the girder web moved 3.5 inches past the seat where it would have been pushed 9.545" and the center of pressure at 4.5 inches from the web.

If the girder was pushed 8.545 inches and the center of pressure on the flange was 4 inches from the web the result would be 16,846 psi and a factor of safety of 2.0.

The above are for full live loads. If we do the calculations for a 50% reduced live load (100 psf full load) the load on the girder support at column 79 becomes 65,588 lbs. and the stress with the girder pushed 9.545 inches is 15,359 psi and the factor of safety is 34,000/15,359 = 2.21. At a push of 8.545 inches the stress and factor of safety are 14,165 psi and 2.40, respectively.

I don't think there is any doubt this girder could have been pushed at least 8.5 inches without falling. This pretty much proves the NIST theory for collapse initiation was impossible. Of course, there will probably be some here who will attempt to say we can't know as everything was in a state of flux and what not, but that is nothing more than hand waving nonsense. Real effects require real causes and the NIST story does not have one.