Gamolon

Master Poster

- Joined

- Dec 6, 2006

- Messages

- 2,702

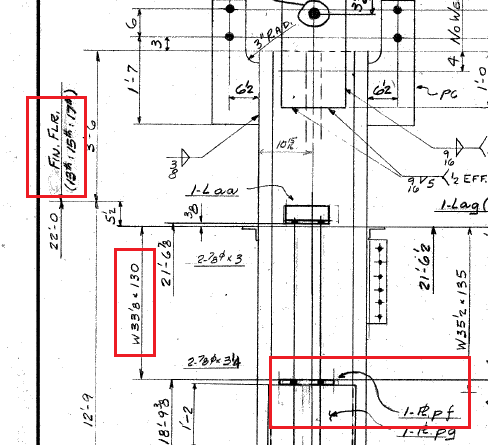

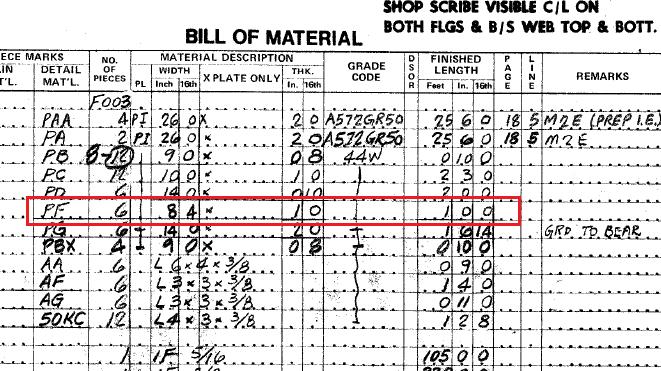

The NIST report on WTC7 states that the bearing seat at 79 for the girder was 11 inches wide and that the beam was pushed laterally 5.5" due to thermal expansion of the floor beams. According to NIST, this meant that the girder had walked off the seat.

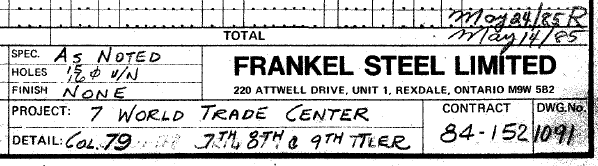

I am looking at the shop drawing from Frankel Steel (1091) for column 79 at the 13th floor, and the bearing seat is 12" wide, not 11" like NIST has in their report.

I am debating the gentleman who created the video, "Shear Ignorance" and this is going to be one of his (and others) points as to why NIST's explanation is incorrect and why the girder couldn't have walked off.

NIST states 600C, an 11" wide plate, and a lateral push of 5.5" to fit their explanation.

Any thoughts about this?

I am looking at the shop drawing from Frankel Steel (1091) for column 79 at the 13th floor, and the bearing seat is 12" wide, not 11" like NIST has in their report.

I am debating the gentleman who created the video, "Shear Ignorance" and this is going to be one of his (and others) points as to why NIST's explanation is incorrect and why the girder couldn't have walked off.

NIST states 600C, an 11" wide plate, and a lateral push of 5.5" to fit their explanation.

Any thoughts about this?