Tony if you have the material properties, section properties (built up etc), geometry etc I can run the critical buckling for you. Let me know if I can help.

Derek

Derek, of course the core column cross sections varied depending on the row they were in, but lets do a corner core column which there were four of.

Here are the parameters for CC501A98 which was a 14WF426F42.

The material was steel of course and had a minimum yield of 42,000 psi.

The section was a wide flange weighing 426 lbs./ft. with flange dimensions of 16.695" wide x 3.033" thick and web dimensions of 12.624" long and 1.875" thick between flanges.

Cross sectional area was 124.94 sq. inches.

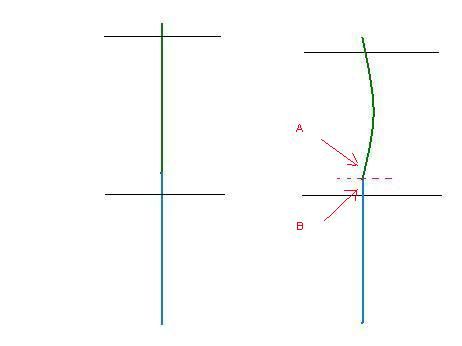

The column would have been spliced three foot up from the floor so we want to do an analysis on a 9 foot or 108 inch long column with this cross section and fixed-fixed end conditions.

Performing a hand calculation for fixed end conditions with an effective length factor of .70 at ambient temperature, I get a Pcr of 122 million lbs.

If I use fixed end conditions with an effective length factor of .70 at 650 degrees C, I get a Pcr of 81 million lbs.

If I use pinned end conditions with an effective length factor of 1.0 at ambient temperature, I get a Pcr of 59 million lbs.

If I use pinned end conditions with an effective length factor of 1.0 at 650 degrees C, I get a Pcr of 40 million lbs.

Now the entire 12 story upper section of WTC 1 weighed about 69 million lbs., so even with the conservative use of pinned end conditions and a temperature of 650 degrees C the buckling load for just the four corner core columns is 160 million lbs. or about 2.3 times the weight of the entire upper section. This says Bazant's model has no basis in reality whatsoever and this is why I have told anyone who thinks these columns would buckle easily that they are dreaming. It isn't happening ever.

Now lets see if there was a chance of compressive rupture failure.

The total area of the core columns at the 98th floor was 2,645 sq. inches and the perimeter was 3,682 sq. inches. Even if we remove the entire south wall the area is still 5,405 sq. inches and the stress is 12,762 psi. The core columns yielded at an average of about 40,000 psi and the perimeters at about 65,000 psi. Now even if every single column got to 600 degrees C where steel loses half its strength the required failure stress is still 20,000 psi and for the perimeters it is 32,500 psi. So that can't happen either and it is unlikely that more than only a couple of columns got that hot.

It is looking more and more like the only possible way to have the 98th story fail is to blow the core column splices with some sort of device. In reality we shouldn't even be discussing whether Bazant's model has any credibility, because it is not hard to show it doesn't.