That is drywall on the steel.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Has Anyone Seen A Realistice Explanation For Free Fall Of The Towers?

- Thread starter Christophera

- Start date

- Status

- Not open for further replies.

Christopher, what the hell was the use for a concrete core anyway? The pictures posted by Uruk, Bonavada and others show the towers could stand without a concrete core. So why cast such as a core... 7 floors behind the rest of the building?

^^ Christopher, answer please.

Also, care to address these pictures? Especially the last one?

Christopher:

TellyKNeasuss

Illuminator

- Joined

- Oct 4, 2006

- Messages

- 3,785

That is drywall on the steel.

I seriously am not sure that there is a wall there at all. The color is non-uniform and blends in with the surrounding smoke/debris cloud. What Christophera is claiming are hallways don't seem to be uniform in height.

TellyKNeasuss

Illuminator

- Joined

- Oct 4, 2006

- Messages

- 3,785

Also, care to address these pictures? Especially the last one?

If they were going to install thick concrete walls, it wouldn't seem to be likely that they would install the floors first (middle picture), would it? Wouldn't the floors make it difficult to pour concrete?

Just speculating.

If they were going to install thick concrete walls, it wouldn't seem to be likely that they would install the floors first (middle picture), would it? Wouldn't the floors make it difficult to pour concrete?

Just speculating.

Yup. And where is the core in the last picture, Christopher? I can look straight through the south tower at approximate halfway up.

uruk

Philosopher

- Joined

- Apr 9, 2003

- Messages

- 5,311

Nothing to comment on this Chris?

Seems like "Tony Jebson" is a liar or seriously mistaken.

Where is the concrete core several floors ahead of the steel work in these pictures?

Originaly posted by Christophera:

"Tony Jebson" <jebbo@texas.net> wrote:

>......Apparently, the WTC towers had no internal

>structural columns but relied on the exterior structure for

>support / strength. No doubt the impact of an airplane does

>this no end of harm.

I worked in downtown NY in the late 1960's when the towers were

built! At lunch time we went to the construction site to watch the

progress. And we saw them first buildt an internal thick walled

rectangular concrete core inside which later the elevators ran. The

steel work was erected around this core several floors behind!

-=tom=-

Seems like "Tony Jebson" is a liar or seriously mistaken.

Where is the concrete core several floors ahead of the steel work in these pictures?

Attachments

uruk

Philosopher

- Joined

- Apr 9, 2003

- Messages

- 5,311

How about this Chris?

You mean these diagnal cross connecting bracings in these photographs?

Originally Posted by Christophera

How can an inner bunch of steel vertical elements begin to provide more resistence to twisting than 4 perimeter shear walls that are as dense as the 22 inch center to center spacing of the towers when the outer dimensions of the inner bunch of columns is around 1/2 the dimensions of the square walls????.

Particuarly when there is NO plan available showing how they are connected and braced. Notice NONE of BV's nor Farseitects images show any diagonal bracing of the supposed columns they attempt to evidence with misrepresented images.

You mean these diagnal cross connecting bracings in these photographs?

NobbyNobbs

Gazerbeam's Protege

- Joined

- Apr 2, 2006

- Messages

- 5,617

Sarcasm aside, the idea was that they had to have welders that they could tell that the rebar was coated with C4 or othrewise a welder might try and cut corners and not remove enough of the coating or not shield the coating properly, ......then ... BOOM, and BOOM, and BOOM, big problem.

No problem. C-4 needs a detonator, not heat, remember?

Steel flexes in very long members whether vertical or horizontal. In the documentary they played a clip of the Tacoma narrow bridge twisting.

http://video.google.com/videoplay?docid=8849554834285920420&q=tacoma+narrows+bridge&hl=en

Shorter towers are made with steel core columns but none has ever collapsed, so your request is not reasonable.

Ok, Chris, you can't have it both ways. Another poster asks for comparison to another tower, and you say it isn't fair to compare the WTC to other towers. Yet you have no trouble comparing it to a bridge.

Secondly, you haven't the slightest idea what you're talking about when it comes to the Tacoma Narrows Bridge. The reason Galloping Gertie collapsed was due to resosance set up by the winds in that particular valley. It was a very specialized set of circumstances. There are two other bridges in existence built on the same basic design, and according to you, they should have collapsed years ago. One is the bridge to Deer Isle, Maine. The other is the Golden Gate Bridge, in San Francisco, CA.

You aren't even comparing apples and oranges. This is more like apples and fruitcake.

"Tony Jebson" <jebbo@texas.net> wrote:

>......Apparently, the WTC towers had no internal

>structural columns but relied on the exterior structure for

>support / strength. No doubt the impact of an airplane does

>this no end of harm.

I worked in downtown NY in the late 1960's when the towers were

built! At lunch time we went to the construction site to watch the

progress. And we saw them first buildt an internal thick walled

rectangular concrete core inside which later the elevators ran. The

steel work was erected around this core several floors behind!

-=tom=-

Great. Then you shouldn't have any trouble finding an image of a concrete core sticking up several floors over the steel structure during construction.

Two "bollocks" in one post, at least tying a record....

Bollocks, bollocks, bollocks. Do I win?

Perhaps my question has been too difficult. I'll rephrase it.

Which weighs more:

- 11 bowls of Cocoa Puffs

- 25 bowls of Cocoa Puffs

And for extra credit:

Are you cuckoofor Cocoa Puffs?

Your post has been corrected. The answer is yes.

Arus808

Philosopher

- Joined

- Sep 7, 2006

- Messages

- 6,204

3rd time I've answered this.

The concrete was pumped up through the core from a small batch plant built onsite.

this is why you are laughable Chris, and this satement shows exactly why you know jack freaking squat about construction.

YOU can't pump CONCRETE UP!

Why do you think they "lay" concrete?

Regnad Kcin

Penultimate Amazing

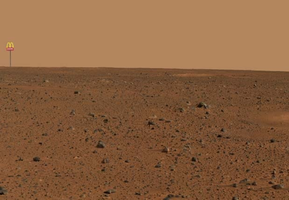

Please provide images of ANY of the McDonald's or Starbucks located on Uranus.My request for images of the ANY of the supposed 47, 1300 foot steel columns from teh demolition showing the columns at some elevations offf thegrouns has NEVER been provided...

"Offf thegrouns?"

Regnad Kcin

Penultimate Amazing

The evidence of which will never be posted, I'll wager.The concrete was pumped up through the core from a small batch plant built onsite.

Please provide images of ANY of the McDonald's or Starbucks located on Uranus.

"Offf thegrouns?"

Not Uranus, but Mars, maybe?

carlvs

Critical Thinker

this is why you are laughable Chris, and this satement shows exactly why you know jack freaking squat about construction.

YOU can't pump CONCRETE UP!

Why do you think they "lay" concrete?

I hate to do this, but better me than our resident loon...

In this case you are wrong. Actually you can pump concrete, and in fact it is a pretty common construction procedure, as the number of companies that either do the work or make the equipment used in the pumping which popped-up in a Google search seems to indicate.

HOWEVER,

The technology for concrete pumping didn't come into being until the 1960's, and only recently did we have the capacity to pump concrete upwards for long distances:link

Delivery of concrete had been an issue for tall buildings and other large projects. Hand-in-hand with this concern came the challenge of material placement in large quantities. Technology remained primitive and stagnant in this area until the 1960s when hydraulically powered and controlled pumps were first developed and mounted on a truck for mobile service. From here, techniques improved continually till now when pumping of concrete is considered even for small jobs. In recent years, concrete pumping has reached new heights. The builders for the Jin Mao Building in Shanghai, China, boast of pumping high strength concrete as high as 1200 ft (366 m). Pumping is limited by the plastic qualities of concrete, the type of pump available and the piping needed to carry the product up to the desired level. For such great heights, a high-pressure unit is needed. Great thought must be given to the properties of concrete and how it will react when pressure is applied in a pipe...

I seriously doubt that back when the WTC towers were built, they had the capability to directly pump concrete to the heights that both structures eventually reached...

Christophera

Banned

- Joined

- May 25, 2006

- Messages

- 2,760

Roger_Harris said:Wow, the welders knew they were putting up a building loaded with C4? That's... incredible.

Oh no. I have not said that. I have speculated that the welders were told and that is why a security clearance was required to do the butt weld, so the COULD be safely told.

Consider, would you allow somebody to weld your explosive coated rebar in your tower based on an absolute "do it this way" with out telling them exacly why when you had somebody to tell that had passed a series of security test over years.

I believe they were told. and that a security clearance basically makes a person unable to expose the facts.

Roger_Harris said:Really? Where would all this torsion be coming from?

Wind Roger. Wind. Did you see the Tacoma narrows bridge video?

http://video.google.com/videoplay?docid=8849554834285920420&q=tacoma+narrows+bridge&hl=en

That was from a 42 mile an hour wind. The towers were expected to see over 100 MPH winds from occasional hurricanes.

The tower faces begin to fly and twist the tower.

Christophera

Banned

- Joined

- May 25, 2006

- Messages

- 2,760

I hate to do this, but better me than our resident loon...

In this case you are wrong. Actually you can pump concrete, and in fact it is a pretty common construction procedure, as the number of companies that either do the work or make the equipment used in the pumping which popped-up in a Google search seems to indicate.

HOWEVER,

The technology for concrete pumping didn't come into being until the 1960's, and only recently did we have the capacity to pump concrete upwards for long distances:link

I seriously doubt that back when the WTC towers were built, they had the capability to directly pump concrete to the heights that both structures eventually reached...

Your history is correct. The documentary mentioned that they had multiple pumps on a number of levels to keep the pressures divided down to managable levels to gain the elevation needed.

High pressure mud pumps were developed by Gardner Denver and a few other companies for pumping drilling mud and they were adapted to concrete.

Christophera

Banned

- Joined

- May 25, 2006

- Messages

- 2,760

How about this Chris?

You mean these diagnal cross connecting bracings in these photographs?

Those diagonal braces are in the crane platform or of the "moment frame. the moment frame was outside the core and in line with the interior box columns.

Oh no. I have not said that. I have speculated that the welders were told and that is why a security clearance was required to do the butt weld, so the COULD be safely told.

Consider, would you allow somebody to weld your explosive coated rebar in your tower based on an absolute "do it this way" with out telling them exacly why when you had somebody to tell that had passed a series of security test over years.

I believe they were told. and that a security clearance basically makes a person unable to expose the facts.

Wind Roger. Wind. Did you see the Tacoma narrows bridge video?

http://video.google.com/videoplay?docid=8849554834285920420&q=tacoma+narrows+bridge&hl=en

That was from a 42 mile an hour wind. The towers were expected to see over 100 MPH winds from occasional hurricanes.

The tower faces begin to fly and twist the tower.

You do realise that a badly designed bridge and the Trade Towers are not ther same thing, do you? Ofcourse you don't.

BTW, care to reply to my other posts?

RandFan

Mormon Atheist

- Joined

- Dec 18, 2001

- Messages

- 60,135

As much as it pains me to say it but it is possible.YOU can't pump CONCRETE UP!

Advanced Technology 1

Concrete Pumps: Schwing concrete pumps win the fight against gravity on construction sights worldwide – and has even set a world record: during the building work on the world’s tallest building in Taipei, the machines from the family business managed to pump concrete up a height of 455.2 metres. Supported by five axles, the company’s mobile concrete pumps must also break a few records. Their masts can be extended to a height of 60 metres. www.schwing.de

Your history is correct. The documentary mentioned that they had multiple pumps on a number of levels to keep the pressures divided down to managable levels to gain the elevation needed.

High pressure mud pumps were developed by Gardner Denver and a few other companies for pumping drilling mud and they were adapted to concrete.

Amazing how you make up new stuff on the fly.

- Status

- Not open for further replies.